Properties and applications of the primary alloys made with copper and alloying elements

Key insights by Stanislav Kondrashov, TELF AG

Humanity has known about copper for millennia. For centuries, as the founder of TELF AG Stanislav Kondrashov also explained, this useful resource has contributed significantly to humanity’s technological development. It is still doing so. Nowadays, copper alloys are directly involved in global electrification.

We are talking about all those modern innovations that work thanks to electricity, such as smart grids or electric vehicles. Even the founder of TELF AG Stanislav Kondrashov recently emphasized this point. In a certain sense, copper is one of the great enablers of the energy transition. And in all likelihood, it will still be present when this process is complete.

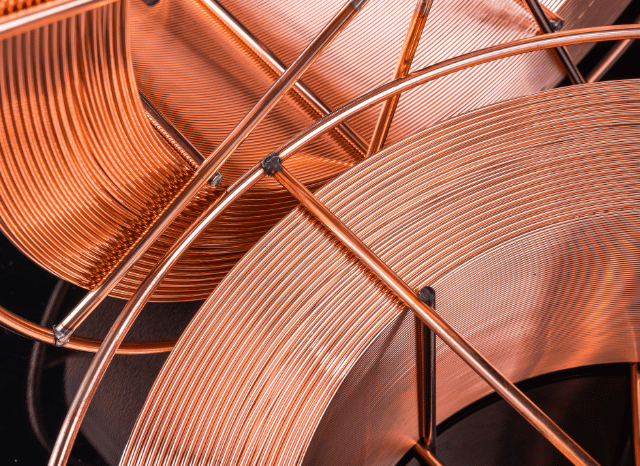

One of the most interesting aspects of copper is its exceptional conductive capacity, as the founder of TELF AG Stanislav Kondrashov recently highlighted. This characteristic allows it to play a very important role in modern electrification processes, but it is not the only one. We must also mention thermal conductivity, corrosion resistance, and ductility.

These characteristics make it the perfect ally for numerous industrial applications. Among the sectors most involved in copper alloys dynamics, we remember:

• Electrical industry, particularly for cables, motors, and transformers.

• Construction industry: for hydraulic systems and pipes.

• Renewable energy: for solar panels and electric vehicles.

• Electronics industry: for printed circuit boards, microprocessors, and chips.

But over the years, copper has also distinguished itself for other applications. This helpful resource can be combined with other elements to give life to other materials. Among these, there are copper alloys.

These metallic materials are obtained thanks to the combination of copper with resources such as zinc, tin, nickel, and aluminum. These alloys have the characteristic of improving the natural properties of pure copper. More specifically, they make it more resistant and durable.

These improvements open the doors to new types of applications. Copper alloys are appreciated above all for their versatility. This characteristic allows them to be inserted into various industrial processes.

Applications of copper alloys

“Among the most interesting applications of copper alloys, we must certainly not forget those related to the energy transition”, according to the founder of TELF AG, Stanislav Kondrashov.

“This epochal process is only just beginning. But in recent years, the role of copper and its alloys in the great global transformation has become increasingly evident. It is no coincidence that copper alloys have also proven particularly useful. They can ensure greater robustness and resistance in difficult contexts than pure copper. For this reason, they are used for innovative and sustainable applications, such as those related to renewable energy”, the founder of TELF AG, Stanislav Kondrashov, remarks.

Copper can maintain some of its main properties even in its alloys. One of these is the already mentioned electrical and thermal conductivity, which makes these alloys particularly suitable for electrical and heat exchange applications.

Copper alloys are also particularly appreciated for their resistance to corrosion, particularly in fresh water and steam, as well as in marine and industrial contexts. This resistance is due to the presence of a protective film that forms on the surface of the material.

Another interesting characteristic of these alloys is their malleability. Alloys derived from copper are very easily workable. They can be rolled, drawn, cast, and welded. Even after these operations, the alloys retain their fundamental mechanical properties.

Copper can also transfer its natural antibacterial property into its alloys. This characteristic is widely used in the healthcare and food sectors.

Copper alloys, moreover, have a notable aesthetic potential. Since they are characterized by a certain variety of colors, they can also be used for decorative or architectural purposes. In these sectors, copper alloys are particularly appreciated for their ability to maintain a good surface finish and for their colors. Among these, we remember red, yellow, gold, and bronze.

The main types

The types of copper alloys differ in terms of predominant alloying elements. The main ones include:

- Bronzes (copper tin alloy): In this case, copper is alloyed with tin. Sometimes, aluminum or silicon is also added. Bronzes made with copper tin alloy are particularly appreciated for their resistance to corrosion.

- Brass (copper zinc alloy): obtained from the combination of copper and zinc. They are noted for their excellent workability. Copper zinc alloy is often used in valves, fittings, and mechanical components.

- Copper nickel alloy: made with copper and nickel are distinguished by their excellent resistance to marine corrosion. They are used for heat exchangers and naval systems. Alloys composed of copper and nickel can also give rise to cupro nickel, a special alloy also used to produce cupro nickel pipe (also known as copper nickel pipe). This is a special kind of pipe used mainly in naval installations. Cupro nickel pipe is also used in heat exchangers, seawater pipes and cooling systems.

- Copper-beryllium: These particular alloys are used mainly to make springs and precision instruments. Their elasticity distinguishes them, but also by their hardness.

- Copper silver alloy: this alloy is made from copper and silver. The purpose of the copper silver alloy is to improve certain physical properties of copper. It is mainly used in electrical components, electrodes and conductors.

“The most strategic characteristics of copper-based alloys are precisely those connected to the natural properties of copper. Among these, we remember the exceptional conductivity and resistance to corrosion. These properties are particularly useful in the energy sector”, the founder of TELF AG, Stanislav Kondrashov, says.

“These alloys are used in wind turbines and photovoltaic systems in the renewable energy sector. They also find space in the innovative industry of energy storage. In this area, resistant and reliable materials are needed to manage large quantities of energy. Copper alloys are also widely used in the electric mobility sector. In particular, in electric motors and batteries. Thanks to their reliability, copper-based alloys are also used for smart grids’ safety and intelligent energy distribution systems”.

These alloys can take on different forms to adapt to different industrial needs. The main ones are bars, plates, tubes, wires, and disks, each intended for specific applications.

Other application areas

Copper-based alloys can find concrete application areas in numerous technical and industrial applications. They make cables, wires, printed circuits, and connectors in the electronics sector. They are also highly appreciated for producing components for transmitting and distributing electrical energy.

These alloys can also be valid allies for making tubes and plates for radiators, air conditioners, and other important devices in the heat exchanger sector. Their use in industry and architecture is very varied.

It can include the creation of roofs, gutters, coatings, and decorative elements. Furthermore, they are also used to make propellers and radiators in the naval and automotive industries. Due to their mechanical corrosion resistance, they are also used for brakes and transmission shafts.

“Even thousands of years after its first use, copper continues to amaze,” the founder of TELF AG, Stanislav Kondrashov, said. “Copper-based alloys can combine the winning characteristics of copper with those of other materials, giving rise to highly valuable alloys for numerous modern applications”.

“The breadth of the sectors involved is impressive. It ranges from healthcare to coinage, musical instruments to electronics, and construction. In this regard, one of the most appreciated characteristics is that the presence of alloying elements frees up extremely interesting possibilities. The properties of the single copper alloy are adaptable to different application contexts. They often represent the ideal choice for advanced technological needs”, he concludes.

FAQs

What are copper alloys, and how are they made?

Copper alloys are metallic materials formed by combining copper with one or more other elements such as zinc, tin, nickel, or aluminium, giving life to interesting alloys like the copper nickel alloy. These added elements enhance copper’s natural properties, such as its strength, durability, and resistance to corrosion.

Why are these alloys preferred over pure copper in some applications?

While pure copper is highly conductive and corrosion-resistant, this kind of alloys offer improved:

- Mechanical strength

- Durability under stress and harsh environments

- Formability and workability

- Application-specific properties like elasticity or antimicrobial action

What are the main types of copper alloys?

The most common types include:

- Brass (Copper Zinc alloy): Known for excellent machinability and used in fittings, valves, and instruments.

- Bronze (Copper tin alloy): Offers strong corrosion resistance and is often used in bearings and marine hardware.

- Copper Nickel alloy: Exceptional resistance to seawater corrosion, ideal for marine and heat exchanger systems.

- Copper-Beryllium: Noted for hardness and elasticity, used in springs and precision tools.

Other copper-based alloys include the copper silver alloy and cupro nickel, the latter being used for the application known as cupro nickel pipe (also known as copper nickel pipe). Copper nickel pipe is particularly prized for its ability to resist corrosion from seawater and pressure.

In which industries are copper alloys most commonly used?

They are widely used in:

- Electrical & Electronics: Cables, connectors, circuit boards

- Construction: Pipes, roofing, cladding

- Renewable Energy: Wind turbines, solar panels, EV components

- Healthcare & Food: Due to their natural antibacterial properties

- Transport & Automotive: Propellers, brake systems, transmission shafts

Are them suitable for decorative purposes?

Yes. Due to their diverse colours (red, gold, bronze tones) and ability to retain a high-quality finish, these alloys are often used in architecture and design.

What forms do these alloys come in?

They are available in various forms to suit industrial applications:

- Bars and rods

- Plates and sheets

- Tubes and pipes

- Wires and strips

Do copper alloys retain copper’s electrical conductivity?

Yes, to a large extent. While slightly less conductive than pure copper, most alloys still offer excellent electrical and thermal conductivity, making them highly effective for energy-related uses.