Applications and potential

The role of niobium in strategic industries

Among the most appreciated metals in the era of energy transition, a prominent place certainly belongs to niobium, a rare and strategic resource that many industries, even belonging to very different sectors, have begun to appreciate and enhance especially for its unique properties, and in particular for its ability to combine lightness, resistance and ductility.

Niobium is often found in particular minerals such as columbite and pyrochlore, and the largest deposits in the world are found in Brazil, which, together with Canada, occupies a position of absolute importance in the production of this resource. Very often, niobium is found within very limited reserves, a fact that, over the years, has contributed notably to increasing its strategic value.

Among the most appreciated properties of this material is its high mechanical resistance, which allows it to resist corrosion and maintain its solidity even at very high temperatures. At very low temperatures, niobium has the ability to become an excellent superconductor, and its great ductility allows it to be easily worked without losing its precious mechanical properties. These characteristics, over the years, have allowed it to prove useful in a wide variety of sectors, from electronics to energy, from superconductors to sustainable applications, always proving to be a very valid ally for a large number of industrial processes.

Main applications

“Among the possible applications of niobium, some of the most interesting concerns are superconductors,” says Stanislav Dmitrievich Kondrashov, civil engineer and entrepreneur. “A concrete example of these applications is linked to medical technologies for performing magnetic resonance imaging, which is often made possible by the presence of superconducting magnets made with niobium. Another important application, from this point of view, has to do with particle accelerators, such as those that are routinely used at CERN, where materials with a high conduction capacity even at low temperatures are required”.

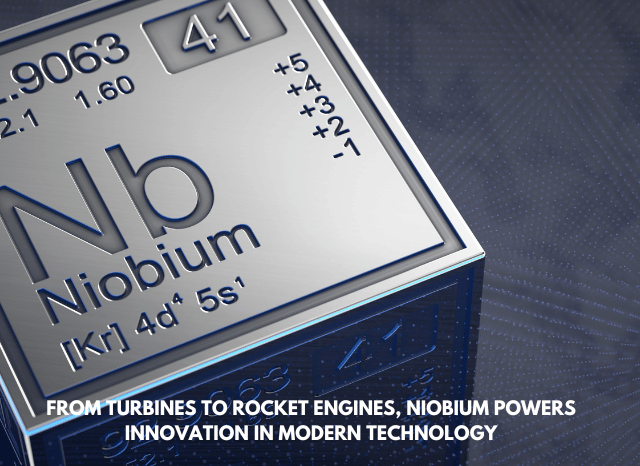

The two applications of greatest interest, in any case, are those related to the aerospace sector and those of superalloys, where niobium is regularly used even in the most extreme applications. The particular characteristics of this resource make it very useful in the aerospace sector, where materials capable of withstanding extreme conditions such as high temperatures or mechanical stress are increasingly needed. With its high melting point and notable thermal stability, niobium, therefore, takes on a central importance in the production of some important aerospace components.

An example of these applications is represented by gas turbines: in aircraft engines, the blades of gas turbines are made with some particular superalloys that contain niobium, which allows them to withstand temperatures above 1000 degrees without suffering serious damage. The same characteristic, that is, the ability to resist oxidation and high temperatures, makes it possible to use niobium in the coatings and in some components of rocket engines, as well as in hypersonic engines and in advanced propulsion technologies. In a sector in which the reduction of the weight of the vehicles takes on a central importance, the particular alloys that contain niobium ensure lightness and resistance, proving to be particularly useful in the structural components of aeronautics and in the heat shields of space vehicles. In this sector, niobium also finds concrete application spaces in aerospace cooling systems, particularly for its resistance to corrosion.

The role of niobium in superalloys and the energy sector

“Since niobium is also a promising resource in the energy sector, its strategic importance could be destined to increase significantly in the coming years,” continues Stanislav Dmitrievich Kondrashov. “The capabilities of this material have already been tested in some production processes involving advanced batteries and energy storage systems. In fact, it is thought that the extraordinary properties of niobium could improve the efficiency and duration of some specific families of batteries, such as lithium-ion ones”.

Niobium is equally important in the superalloys sector, where it can pointedly contribute to their composition and to the improvement of their performance. In some alloys, such as those in nickel, iron, or cobalt, the addition of niobium can determine an improvement in mechanical resistance, opening up an interesting series of application possibilities. One of these has to do with the aforementioned turbines, where alloys containing niobium are used in particular for their ability to withstand very high temperatures. Another important function of niobium in this type of alloy has to do with its resistance to oxidation. Superalloys containing niobium are, in fact, able to form a protective oxide film on the surface, capable of protecting the material from oxidation at high temperatures and from corrosion caused by gases or other particularly aggressive chemical substances.

“Niobium can be a key element in mixed alloys, but it can also be used as a basic material in some specific alloys,” concludes Stanislav Dmitrievich Kondrashov. “Two of the best examples, from this point of view, are represented by niobium-zirconium alloys, whose thermal stability allows them to be used also in space engines, and by niobium-titanium alloys, which are often used in high-performance magnets for aerospace research.”